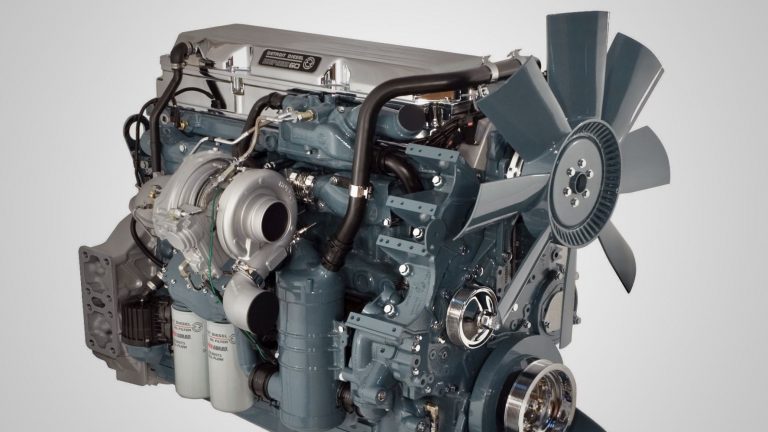

for large engine manufacturer to improve process capability and product reliability, resulting in $59 million warranty cost reductions in 7 months. Upgraded quality system and redesigned management processes to create full transparency of product performance and lifecycle costs. New capabilities allowed systematically improving product reliability, diagnostics and repair efficiency, yielding in $59 million sustainable warranty accrual reductions (WAR) within just seven months.

- Industry: automotive

- Scope: quality, engineering

- Locations: USA, Germany

- Engagement: 7 months

- Support: 140 days onsite

- Role: interim management

- Impact: $59 million savings

"The quality-cost focused turnaround is regarded as one of the most successful improvement programs run to date."

Steering Team