Operations Consulting for a More Efficient World

«eliminating operational losses so that every bit of time, material, and energy is used to create value for humanity»

We help business leaders turn failing operations around so they can meet expectations, and advance good operations to a world-class level so they can produce more without adding headcount or spending capital, while coaching managers and specialists, turning them into effective change champions to sustain success.

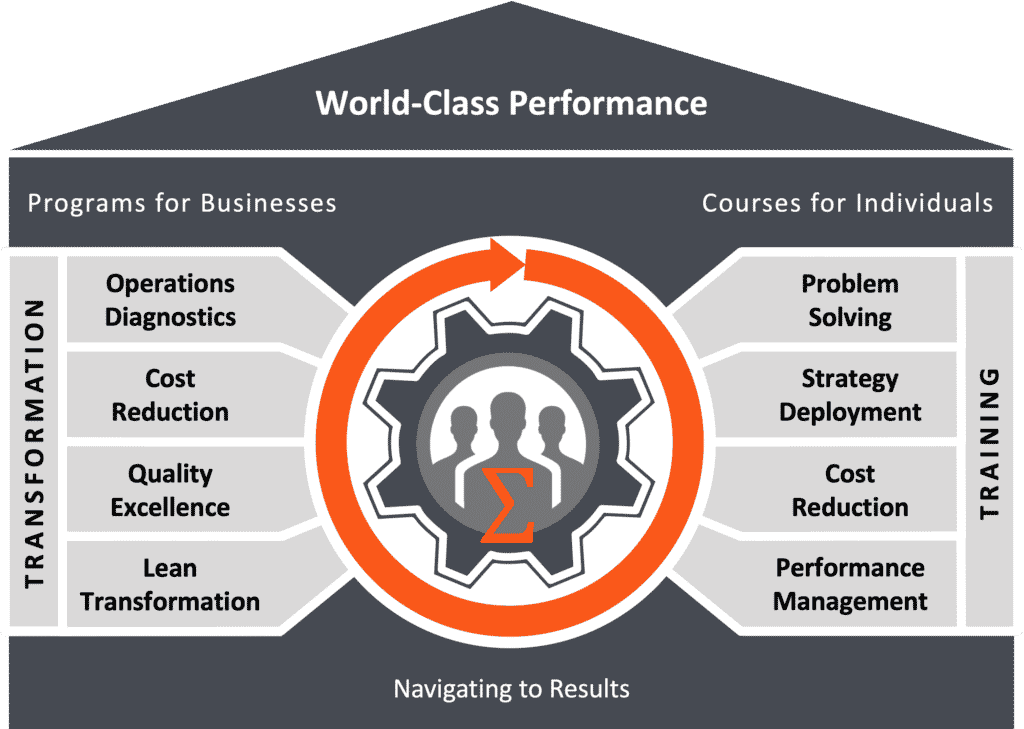

Transformation Programs

For businesses we identify improvement potentials and develop transformation programs to get ahead of competitors.

Training Courses

For individuals we offer targeted training programs to build solid skills that create measurable gains and advance careers.

+30% Performance in 9 Months

“Navigating to Results” means enabling clients to deliver results they never thought possible, delivering 30% performance within 9 months at a predefined scope and scale. Using a dual-track approach of operations consulting programs (“Performance Booster”) and capability-building courses (“Skill Booster”) drive continuous improvement, bringing clients one step closer to world-class operations, even if that goal seems completely out of reach at the beginning.

Performance Booster for Businesses

Providing business leaders with the ‘Performance Booster’, a 9-month transformation program that translates ambitions into solid strategies and roadmaps, acting like a compass to steer through uncharted terrain and break through the performance barrier under the guidance of a coach. Weekly sprint reviews ensure clarity and accountability that make the KPI-needle move, earning the recognition of customers and constituents, and inspiring peers to follow suit.

Career Booster for Individuals

Providing managers and functional specialists with the ‘Career Booster’, consisting of 3-9 month training and certification courses to build future-proof skills, applying battle-tested tools to solve performance problems and achieve breakthrough results under the guidance of a coach. Weekly sprint reviews ensure clarity and accountability that make the KPI-needle move, earning the recognition of customers and colleagues alike, while clearing the path for career advancement and better pay.

Operational Problem? Consider It Solved!

Clients come to us for Operations Consulting advice, training, and hands-on support to solve their most-pressing manufacturing and service problems. As a result, they systematically close performance gaps, deliver on their commitments, advance to a world-class level, and no longer have to fear the competition.

Operational Excellence Consulting for Competitive Advantage

Transformation programs for manufacturers and service-providers to achieve goals with less time, effort, capital – while creating an unbeatable competitive advantage.

Lean Questionnaire for Business Benchmarking

Do you operate at a world-class level? Take the lean-questionnaire to determine operational health and maturity level relative to best-in-class organizations.

Operations Academy for Career Advancement

Training courses for result-oriented leaders, managers, and functional specialists to build future-proof skills that accelerate careers, supported by an expert coach.

Operational Excellence and Lean Tools, Templates, Trainings

Download free tools and templates, buy professional toolkits and guidebooks, upgrade your membership plan, and book training and consulting sessions.

The 5 Reasons Why Clients Hire Leanmap

- Deep knowledge and expertise to deliver performance improvements in manufacturing, technology, and service operations.

- Strengthen teams in the role of an advisor and coach ('light touch') or program leader and interim manager ('strong lead').

- Hands-on approach from seamlessly integrating with client-teams, co-invent solutions, jointly remove barriers, drive results.

- Full flexibility to adjust the level of support: scale-up when more influence is required and ramp-down as capability matures.

- Lasting impact from solving operational business problems that create a better future for customers, employees, and owners.

Facts & Figures

Operations Consulting Since 2005

Turning Challengers Into Champions

Are you faced with rising costs, disappointed customers, unreliable deliveries, or too many defects and delays? We can help you overcome these challenges, with Operations Consulting to develop effective solutions and Lean Management to implement them. After an initial pilot, over 90% clients embark in a full-size transformation program that makes them champions within their industry, so they never have to struggle with eroding profitability or red scorecards again.

Construction: Developing Offsite Manufacturers to Build Mega City

Supplier Certification System (SCS) to systematically assess, certify, and develop offsite manufacturers to build the futuristic mega-city in Saudi Arabia in record time and efficiency.

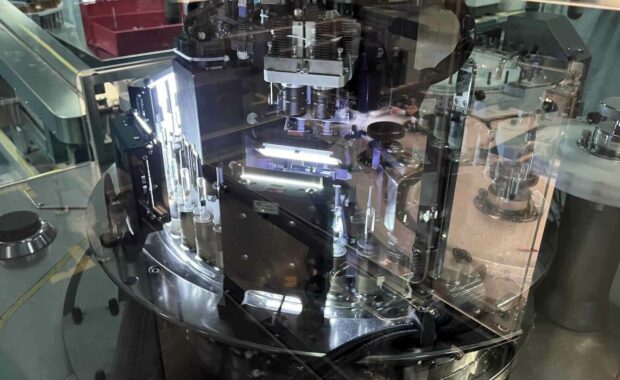

Pharma: Improving Production Efficiency to Help More Patients

Production Efficiency Program (PEP) for a French pharmaceutical plant to increase filling-rate of thrombosis-therapeutics +32%, closing a growing gap between plant output and patient demand.

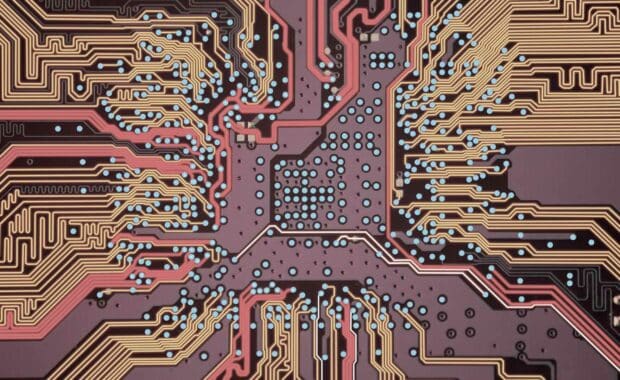

Materials: Solving Bottlenecks to Boost Throughput

Overall Equipment Effectiveness (OEE) improvement of printed circuit board production through systematic elimination of 68% flow-stoppers in just two months using Fault Tree Analysis (FTA).

Semiconductors: Cost-per-Move Reduction to Save the Budget

Cost Savings Program (CSP) for a major chip manufacturer reduces Cost-Per-Move (CPM) through adaptive maintenance, systematic barrier removal, and rigorous performance management by $118 million.

Energy: More Reliable Heat for More People

Lean Transformation Program (LTP) for Kvitebjørn Varme to realize its vision to become Norway’s most reliable energy-supplier, delivering more heat, more consistently to more people.

Plastic Film: Path to World Class Manufacturing

Lean Transformation Program (LTP) for an European polyethylene packaging film producer to bring plants on path to world-class manufacturing (WCM), while boosting yield and productivity.

Ship Service: Performance Improvement Program

Performance Improvement Program (PIP) for the world’s largest ship supplier to improve operating efficiency of regional centers in Europe, Far East, Middle East, and USA.

Rock Tools: Lean Development Cuts Time-to-Market

Lean Product Development (LPD) for a major supplier to the mining and construction industries, reducing time-to-market (TTM) of new developments by 35% within 2 years.

Automotive Safety: Audits for Future Factory Design

Lean Operations Diagnostics (LOD) for the largest automotive safety supplier, assessing main manufacturing sites and development centers to deliver critical inputs for the factory-of-the-future design.

Beverage Production: PDCA Cuts Non-Quality Costs

Quality Excellence Program (QEP) for a global ingredients manufacturer to reduce first-time-incorrect (FTI) rate of product mixes delivered to the world’s largest non-alcoholic beverage companies.

Pharma: Lean Audit for Operations Improvement

Lean Operations Diagnostics (LOD) for a European pharma company to assess manufacturing maturity, while identifying improvement potentials for throughput, yield, flexibility, overall factory efficiency (OFE).

Food Flavors: Journey to World-Class Efficiency

Lean Transformation Program (LTP) for the largest food flavor and fragrance company to streamline operations end to end, achieving industry-leading profitability from world-class operating efficiency.

Power Electronics: Complexity Cost Reduction

Cost Reduction Program (CRP) for Eltek, a global electric power conversion specialist, to reduce the cost base by optimizing interfaces between engineering, operations, and sales.

Waste Recycling: Lean Sorting & Processing

Lean Transformation Program (LTP) for Norway’s leading environmental services provider to boost operational efficiency by applying Lean management principles to the seven largest processing plants.

Sporting Goods: Operational Due Diligence

Lean Operations Diagnostics (LOD) for private equity as part of the pre-acquisition due diligence program with focus on four European factories to identify value-creation opportunities.

Industrial Manufacturing: Continuous Improvement

Continuous Improvement Program (CIP) for a Swiss industrial manufacturer makes 13 European factories competitive again by increasing 6-12% in productivity, speed, and quality each year.

Transport & Logistics: Cost Reduction Program

Cost Reduction Program (CRP) for a large industrial multinational with focus on transport and logistics, delivering $15 million annualized savings within the first 4 months.

Energy Metering: Quality Program Cuts Cost

Quality Excellence Program (QEP) for a global energy metering company with focus on product reliability to reduce field-failure rates and costs for warranty and repair.

Diesel Engines: Warranty Cost Reduction

Quality Excellence Program (QEP) for large engine manufacturer to improve process capability and product reliability, resulting in $59 million warranty cost reductions in 7 months.

Military Vehicles: Lean Assembly Shortens Lead-Time

Lean Transformation Program (LTP) for the leading truck manufacturer to resolve constraints in assembly and logistics, meeting critical deliveries of military vehicles to the front-line.

Marine Electronics: Lean Management Turnaround

Lean Transformation Program (LTP) to boost manufacturing output of the leading marine-electronics company by de-bottlenecking its main factory in Mexico and rationalizing the manufacturing footprint.

Airline Catering: Labor Productivity Cost Reduction

Cost Reduction Program (CRP) for global airline caterer to meet top-down profitability target by transforming seven factories with focus on planning, manning, manufacturing and logistics.

Household Appliances: Factory Consolidation

Cost Reduction Program (CRP) for a household appliance manufacturer in China to significantly reduce operating costs by merging two assembly factories, right-sizing the manufacturing footprint.

Our Clients

Working With Us, You Are in Good Company