Receive the prestigious Lean-Certification award for maturing your operation to level 2-Bronze, 3-Silver, 4-Gold in Lean-Manufacturing and Lean-Service.

Have your company evaluated by an expert and receive the Lean certificate in Bronze, Silver, or Gold after passing the physical audit. The Lean Certification sets you apart from your competitors. It recognizes manufacturers and service providers who have demonstrated operational excellence. The company must apply for the award, followed by a comprehensive on-site assessment. After maturity is confirmed by the auditing expert, you receive the Lean Certificate that recognizes you and your team for this great achievement.

- For manufacturing and logistics companies

- For engineering and product development

- For healthcare, hospitals, doctors, laboratories

- For call centers and back office operations

- For professional service, general management

- Get audited and certified at Bronze, Silver, Gold

- Based on Lean Operational Excellence practices

The 3 Lean Certification Levels

Maturity is measured on a five-point scale, ranging from the lowest level ‘Iron‘ (1 point) to the highest level ‘Diamond‘ (5 points). Formally certified levels are Bronze, Silver, Gold. Each of those maturity milestones is characterized by a distinct starting point, focus area, and outcome.

Bronze | Maturity 2.0

- Major effort to keep running

- Fire-fighting, barrier-removal

- Problem hot spots contained

Silver | Maturity 3.0

- Targets met with extra effort

- Reducing waste, variability

- Repeatable processes, results

Gold | Maturity 4.0

- Consistently strong results

- Value stream management

- Solid systems, skills, standards

About Assessment Process and Lean Certification

Who is getting an award?

The Lean award recognizes companies that demonstrate excellence against the award guidelines and evaluation criteria (→ “The 20 Keys to World-Class Operations“). Any applicant passing the initial screening interview (→ Book now) will be considered for an award.

Why getting certified?

The primary purpose of a certification is to acknowledge the progress made, learn from best practices, and foster an environment of creativity and innovation, while continuously improving performance levels.

Why focusing on Leanness?

Lean standards allow manufacturers and service providers operate effectively and efficiently. As prerequisites for attaining Operational Excellence, these standards help companies increase productivity, shorten lead times, improve service quality, capture new customers and gain access to new markets through rapid response and just-in-time delivery.

How long does it take?

The onsite audit (‘Quick Scan‘) takes 3 days, which includes Gemba walk, process mapping, performance review, and expert-guided assessment. The audit can be extended by 2 days (‘Scan+Plan‘) to develop the transformation projects and roadmap, define business cases, and calculate financial impact (ROI) of individual projects and the transformation program overall.

How to prepare for the audit?

Applicants gather their team and complete the free self-assessment to create awareness and to learn about the 20 keys. The user-friendly questionnaire allows professionals from various backgrounds with varied skill sets to assess the level of operational health and maturity without extensive training (→ Audit Now).

What are the benefits of going through this process?

The Lean certification process not only validates status and progress, but provides coaching feedback and formally recognizes the team for advancing their operation, creating motivation and insights to prepare for the next phase on their journey to world class → see pictures below.

How many audits are required to get certified?

At least two measurements are required to confirm that the audited organization has achieved and maintained the level of maturity as assessed by the audits. The certification process is an extension of the auditing process, which provides both the baseline and subsequent progress measurements.

How does the audit process work in practice?

Suppose an organization measures 2.7 on the first assessment. This initial measurement does not warrant a certificate; rather, it establishes the baseline for a certificate. Several months later, the audit is repeated to determine progress relative to the baseline. For example, the team was able to mature by +0.4 point with an overall score of 3.1, which justifies awarding a Silver certificate.

What does the audit score actually mean?

Tracking maturity is like tracking atmospheric pressure with a barometer; it provides a clear indication of changing weather conditions. Maturity gain, as established by the 20 Keys, is therefore a leading indicator that complements financial reports that are comprised solely of lagging indicators.

How does the score help to improve?

Making fundamental changes in structure or capability will be reflected in the maturity score (leading indicator), but it may take months for it to affect financial reports (lagging indicator). The 20 Keys provide a reliable forecast for future performance; the principles and processes are described in detail in the Lean Audit book.

What happens when the target is met?

When attaining target maturity, the event should be formally communicated and celebrated in the same fashion as when achieving a significant financial goal or capturing a new valued customer. After all, it is a milestone in an organization’s evolution.

Why celebrate the certification?

Because more mature companies do better than less mature ones, so an improving score in the Lean Audit—along with certification—suggest better operating results in the near future. It is a good reason to recognize people for their extra effort to move the organization forward.

What clients think about the Lean Certification:

"The process of the audit itself is enlightening to all participants and as each answer is agreed within the team, gaps and next steps are very clear to them."

Lean Manager, Argentina

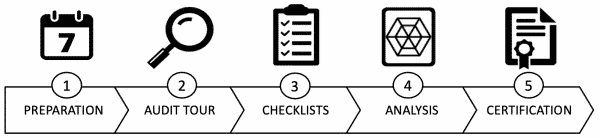

The 5-Step Lean Certification Process

Step-1: Preparation

The leader specifies the purpose of the audit, to be either benchmarking, self-assessment, progress measurement, or opportunity discovery, and nominates the members of the audit team to include representatives from all key functions that make up the assessed site or value stream.

Step-2: Audit Tour

The members of the internal audit team walk together with the external auditor through their value streams in flow direction from input to output, evaluating people, processes, setup, and system (→ Gemba Walk).

Step-3: Checklists

The audit team meets in the conference room for a guided self-assessment, moderated by the external auditor or internal team leader. The moderator validates assumptions with the team and ensures that the correct level is selected, meeting all stated criteria.

Step-4: Analysis

Translating insights into improvements. Led by the external auditor or internal group leader, the team decides on an ambitious yet realistic advancement rate, taking the target minus baseline, divided by the number of years to accomplish the target.

Step-5: Certification

After the progress measurement is established, the team compares the current score against the goal, defined during the previous audit. Two things must occur for certification: the target maturity has been attained at an advancement rate of +0.15 per year or higher.

100+ Companies Certified Worldwide

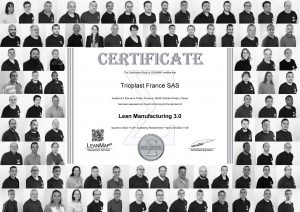

Plastic Production: Increasing Yield, Flow, Resilience during Pandemic

Trioplast, one of Europe’s leading manufacturer of polyethylene film for cost-effective packaging solutions embarked on a systematic Lean rollout in 2018 to transform its operations.

Industry 4.0 Meets Lean: Faster Waste Processing at NG

Gemba walk during Lean audit confirms measurable improvements across all business-critical dimensions, such as employee engagement, structural stability, sorting quality, equipment reliability, and operational productivity.

DISA Sets Internal Lean Benchmark for Norican Group

The Danish manufacturer of foundry equipment reached Silver level, improving schedule-adherence from 33% to 82%, cutting rework and overtime by 50%, increasing productivity by 20%.

Training Wrist’s Staff in Pursuit of Lean Ship Service

With focus on warehouse and back-office operations, 614 champions completed their Lean projects, improving response time to customers and on-time-in-full (OTIF) delivery performance to vessels.

Lean Manufacturing Award for Givaudan Indonesia

Three years on its Lean journey the Indonesian team streamlined manufacturing-logistics chain, maximizing throughput to better serve the growing demand of Southeast Asia’s largest economy.

Lean Manufacturing Silver-Gold for Givaudan Japan

Factory assessment confirms that the Fukuroi operation matured to ‘Silver-Gold’ level; now able to serve the Japanese beverage industry with quick-turn and highly flexible deliveries.

Lean Manufacturing Award for Norsk Gjenvinning

Norsk Gjenvinning’s metal shredding operation in Øra near Fredrikstad has made the Silver mark by attaining maturity level 3.0 on the five-point Lean benchmarking scale.

Lean Manufacturing Award for Givaudan USA

In pursuit of Operations Excellence the factory team in East-Hanover significantly improved first-pass yield (FPY) and on-time delivery (OTD), producing flavors with much improved consistency.

Lean Manufacturing Award for Givaudan Brazil

Team São Paulo matured its food-ingredients factory to level 3.5 on the five-point benchmarking scale; received ‘Silver-Gold‘ award for achieving breakthroughs in yield and productivity.

Lean Manufacturing Award for Givaudan Singapore

Continuous effort over nearly five years paid-off: by systematically upgrading skills and capabilities, the Woodlands-team was able to significantly increase right-first-time (RFT) and labor productivity.

Lean Manufacturing Award for Givaudan South Africa

Milestone achieved after a 4-year Lean journey, the operations team in Johannesburg proudly presents its ‘Silver‘ award for achieving level-3 on the Lean benchmarking scale.

Lean Manufacturing Award for Givaudan Hungary

The operations team in Hungary brought the largest powder blending factory of the group to ‘Silver‘ by implementing in core manufacturing and critical support processes.

Lean Manufacturing Award for Navico Mexico

Navico’s maquiladora in Baja California received the ‘Silver‘ award for attaining maturity level-3 in Lean Manufacturing, boosting productivity 42% year-on-year and 1100% over seven years.

Lean Manufacturing Award for Singaporean Factories

Two flavor factories received Silver-awards for scoring 3.0 points on the Lean Manufacturing benchmarking scale, while better delivering liquids and powders to the food industry.

Lean Manufacturing Award for Givaudan Mexico

A comprehensive Lean rollout brought the operation in Cuernavaca to ‘Silver‘, covering the value-chain including planning, production, logistics, customer service, maintenance, quality, and human resources.

Lean Manufacturing Award for Givaudan Argentina

Improving at a world-class rate of +0.5 point per year on the lean manufacturing benchmarking scale, the leadership team in Buenos Aires truly transformed its operation.

Lean Manufacturing Award for Givaudan Australia

Team in Smithfield “moved the performance needle” by implementing the Leanmap toolkit: Strategy Deployment Framework (SDF), Performance Management System (PMS), and Systematic Problem Solving (SPS).

Lean Manufacturing Award for Givaudan Netherlands

The Dutch team was first setting up the performance management center, the central place where the cross-functional team meets daily to plan and solve problems.

Lean Manufacturing Award for Givaudan Germany

The team in Dortmund benchmarked its factory and matured it over a two-year transformation period to ‘Silver‘ level, scoring 3 points or 60% operational excellence.

Lean Manufacturing Award for Givaudan Switzerland

Lean Audit confirms ‘Silver’ maturity for Givaudan’s major processing plant in Switzerland. The site was first to make the ‘Silver‘ mark, attaining maturity level 3.

Lean Manufacturing Award for Eltek Slovakia

Systematic application of Lean principles allowed Eltek‘s module assembly plant in Slovakia significantly reduce cycle times and defect rates, permanently lowering the manufacturing cost base.

Lean Bronze Award for Boosting Metal Sorting Efficiency

Lean Transformation Program (LTP) allowed NG’s metal sorting plant reduce throughput time by 80%, inventory by 25%, and double-handing by 80% in just 1.8 years.

Lean Award for Industrial Waste Sorting Efficiency

Lean Transformation Program (LTP) for industrial waste processing sites in Knarrevik and Mongstad to establish flow, processing batches faster and more efficient than ever before.