Building a "Lean Machine" to consistently deliver outstanding results that delight customers, are envied by the competition, and blow investors away.

The most successful companies and individuals are never satisfied with the status quo. They constantly look out for the next innovation, better ways to do things, and adjustments to daily routines that unlock hidden potentials and bring them to the next level. But these repeat successes do not just happen by accident or by communicating an ambitious strategy, they are the result of a robust Lean Process that systematically drives Performance Improvement.

Lean Process for Systematic Performance Improvement in Manufacturing, Development, Service

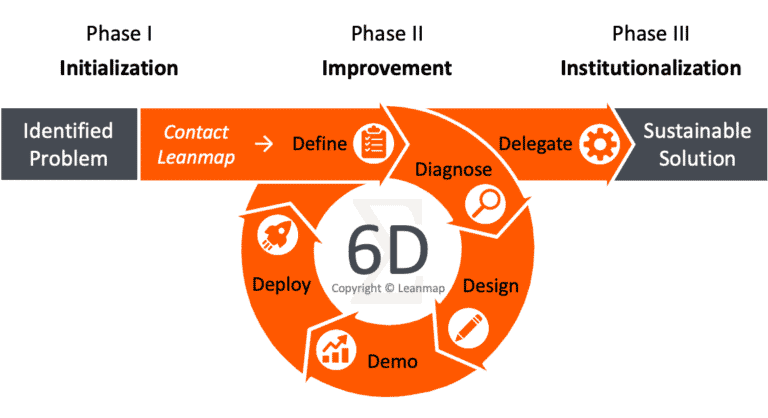

To be effective, a performance improvement process must support a clear understanding of current gaps and limitations, effective solutions to overcome identified barriers, disciplined implementation and embedment of new the way of working in culture and operating system. Our 6D Improvement Process was developed just for this purpose. It keeps people focused and the project on track. It ensures that performance improvement is not only discussed but also achieved. What’s more, following the 6D steps ensures continuity and sustainability by creating a triple benefit for customers, investors, and employees.

6D Steps:

1. Define the project charter to describe the problem to solve and the goal to achieve;

2. Diagnose the current state to identify the root causes and improvement levers;

3. Design the future state to solve the problem and define the implementation plan;

4. Demonstrate impact at pilot scope to validate the solution and confirm effectiveness;

5. Deploy the solution at full scope, while training people and tracking performance;

6. Delegate ownership and standardize processes to embed the solution and sustain success.

The 6D Lean Improvement Process Guides Teams from Identified Problem to Sustainable Solution

The process start with the identification of the problem, the gap between what is now (baseline) and what is expected (goal) or what is possible (entitlement). This gap is then addressed internally or with the support of an external expert. During the initial consultation we help you define the problem statement, identify solution approaches, select the most suitable path, and simulate financial impact. From here, you can take it in your own hands or hire us to lead your team through the performance improvement process: I-Initialization, II-Improvement, III-Institutionalization that delivers measurable gains in six focused steps: D1-Define, D2-Diagnose, D3-Design, D4-Demonstrate, D5-Deploy, D6-Delegate. Quality gates after each step ensure deliverables being met before moving to the next step. Although the 6D method may seem like a classic stage-gate process (waterfall), it actually works based on agile principles because the performance improvement cycles are short and frequent, so each sprint delivers a measurable gain and serves as a launching pad for the next cycle.

D1 - Define

• Define Project

• Develop Charter

• Set Objectives

✓ Project Defined

D2 - Diagnose

• Diagnose Problem

• Identify Root Causes

• Quantify Opportunity

✓ Analysis Completed

D3 - Design

• Design Solution

• Simulate Impact

• Plan Implementation

✓ Solution Developed

D4 - Demo

• Demonstrate Impact

• Adjust Parameters

• Confirm Effectiveness

✓ Solution Validated

D5 - Deploy

• Deploy Solution

• Train People

• Track Performance

✓ Solution Installed

D6 - Delegate

• Delegate Ownership

• Standardize Method

• Communicate Impact

✓ Solution Embedded

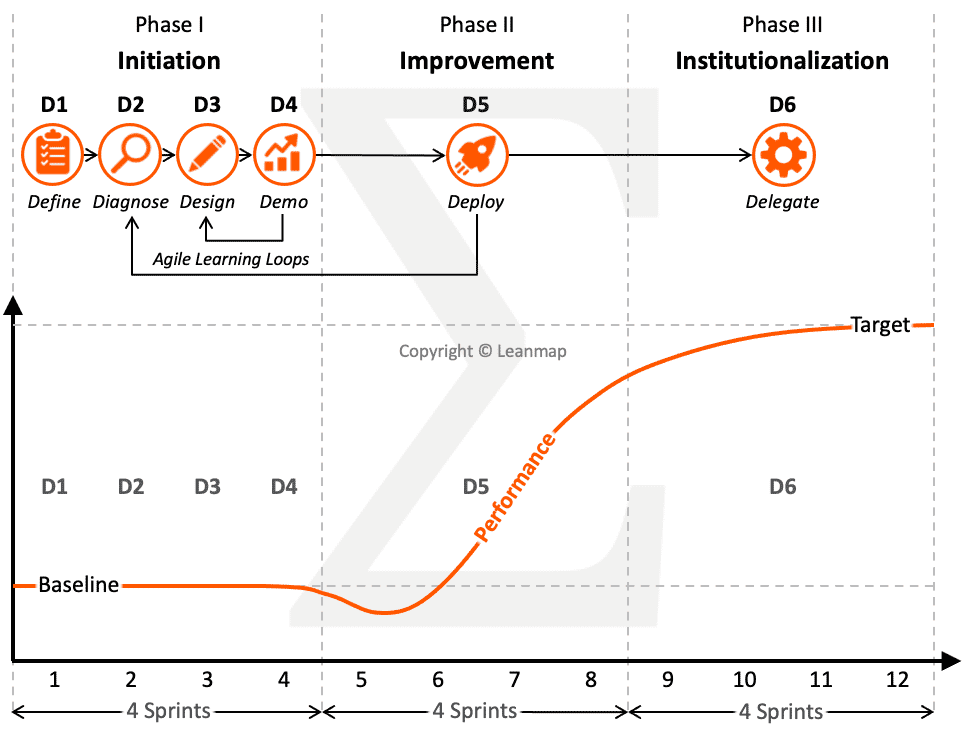

The 6D Lean Process Drives Systematic Performance Improvement Through Rapid Learning Loops

The basic principle behind the 6D process is to develop a robust solution through repeated cycles (iterative) and in a small scope at a time (incremental). Two feedback loops ensure quick learning, between D4-Demo and D3-Design, and between D5-Deployment and D2-Diagnostics. It allows the team to validate assumptions during pilot runs, testing solution components under real operating conditions (full scope) or the entire solution system under controlled conditions (limited scope). It starts with a simple implementation of a subset of the solution and iteratively enhancing the evolving versions until the full solution is operational. At each iteration, parameters are adjusted until the desired performance levels are achieved.

Planning Project Timeline with Sprints and Deliverables

We are designing and implementing the solution in 3 phases and 12 sprints, at 4 sprints per phase. Each sprint is formally planned and impact reviewed with your team, so that learnings are captured and applied to the next iteration of the solution design. Doing so not only accelerates the process but also keeps people engaged and the project on track, delivering a more robust und sustainable solution overall.

Why Performance Gets Worse Before Getting Better

Naturally, any meaningful change creates instability by disrupting the status quo. As a result, performance dips at first, before turning around and taking off as improvements take root. As performance approaches the target level, changes are being embedded in the way of working (WOW) by standardizing methods and reinforcing behaviors, making processes repeatable, results reproducible, and success sustainable. The newly established performance plateau becomes the launchpad for the next improvement cycle.

The Leanmap Way - What We Do Differently

Instead of leaving you with a large powerpoint presentation to work through, we co-invent the solution together with your team, jointly discovering and deciding what works best. Such process takes a bit longer at the beginning (front-loading effort) but it eliminates the extra effort later on to convince people getting on board. We stay fully engaged and support you during the critical change period, until improvements are implemented, impact is achieved, skills are transferred, and systems are in place to sustain them: “Navigating to Results”.

6D Lean Process for Strategy

helps leaders define and execute strategy, supports those activities:

- Benchmark and conduct competitive analysis

- Analyze and solve operational constraints

- Develop business and growth strategies

- Define required skills and competences

- Develop location and value-added strategies

- Rationalize structures and streamline processes

- Bring mission-critical projects on track

6D Lean Process for Operations

helps teams deliver performance improvements in the following areas:

- Manufacturing and service operations

- Research and product development

- Sourcing and supply chain management

- Quality assurance and management

- Productive maintenance and asset-care

- Sales, marketing, and after-sales service

- Business planning, finance and controlling

"Navigating to Results" means accelerating your performance improvement process, so you get there faster.

Lean Consulting and Lean Management for Top Results

We help manufacturers and service providers with rapid performance boosts, resulting in significantly-lower cost and a stronger market position long term.

Leanmap Consulting for Operations Transformation

We offer expertise, coaching, and hands-on realization support for manufacturers, technology firms, and service providers to set operational benchmarks with Lean.

Lean Consultant and Lean Manager on Demand

Helping leaders close performance gaps and advance capabilities to reach operational benchmarks, so they never have to fear the competition again.

Consultant Role for Optimal Support and Impact

Strengthening an organization with external skills and expertise requires a clear definition of organizational setup, type of intervention, roles and responsibilities.