Cost Savings Program (CSP) for a major chip manufacturer reduces Cost-Per-Move (CPM) through adaptive maintenance, systematic barrier removal, and rigorous performance management by $118 million.

The Situation:

After laying off off hundreds of employees to cut costs, the technology company continued making losses despite rising revenues. Investors were very unhappy with the persistent underperformance and demanded a thorough diagnostics – baselining foundries in US, DE, SG – to understand the causes as basis for developing a cost improvement program.

The Problem:

Fabs were underutilized, which poses a major problem for capital-intensive industries such as semiconductors, where processes and systems are designed to operate over 80% capacity to absorb the extreme costs of equipment, energy and engineers. The combination of slowing demand, rigid systems, high process variability, and ineffective management responses resulted in large losses that were increasing at an accelerating rate.

The Solution:

Implementation of a custom-designed Factory Cost Reduction (FCR) program to achieve break-even at lower loading levels through adaptive maintenance to increase the uptime of critical tools with fewer interventions, systematic elimination of production flow barriers, rapid chip-design improvements to reduce variability, and rigorous performance management to implement improvements faster.

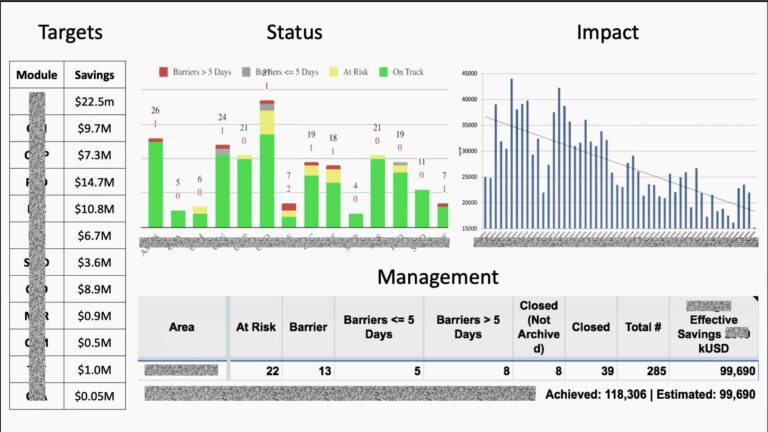

The Impact:

During a nine-month transformation period, 285 cost improvement projects were identified across 10 engineering teams with more than 5,000 tasks executed that reduced Cost Per Move (CPM) and delivered a $118 million in annual savings (run rate). Challenging methods and mindsets helped people overcome ineffective practices and develop new ways of working in a complex technology-centric environment.

Facts & Figures

- Industry: semiconductors

- Revenue: USD 5.5 billion

- Employees: 16,000 global

- Fabs: US, DE, SG

- Scope: US fab

- Engagement: 9 months

- Support: 72 days onsite

- Role: cost reduction expert

- Savings: USD 118 million

Client Feedback

"Excellent advice and solutions offered; practical coaching and application of principles in a real way while understanding the realities of our environment. Strong engagement skills and willing to work deeply with teams to both challenge and encourage progress towards an ideal state. The program has enabled a revamp and installation of a completely different mechanism for driving cost improvement."

VP Operations, USA