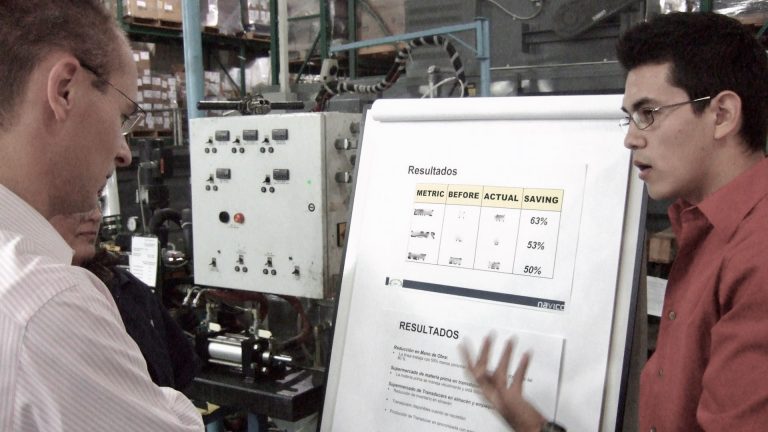

to boost manufacturing output of the leading marine-electronics company by de-bottlenecking its main factory in Mexico and rationalizing the manufacturing footprint. The focused improvement program delivered several breakthroughs: 44% gain in labor productivity, 53% floor space freed up, 94% reduced process inventory, and 66% higher first-pass yield. Operational improvements added $8 million to the bottom line within the first 12 months. The systematic application of Lean principles allowed the cross-functional team to simultaneously improve product design, stabilize processes along the critical path, build the organization, revamp the management system, and rationalize the manufacturing footprint. As a result, productivity increased +42% year-over-year, totaling 1100% (eleven-fold) productivity gain over seven years. The stellar performance record sparked the interest of investors, so that Goldman Sachs acquired Navico in July 2016.

Facts & Figures

- Industry: Electronics

- Scope: Operations, Logistics

- Sites: MX, US, NO, NZ

- Project: 12 months

- Support: 300 days

- Role: Interim Manager

- Productivity: +44%

- Inventory: -94% WIP

- Quality: +66% first pass

- Savings: $8 million, 1st year

- Advisor: for 8+ years

Client Feedback

"Joerg Muenzing has been instrumental in the process of fundamentally improving Navico. He is committed and results-driven, having spent 12 months helping Navico transform its manufacturing operations globally to ensure successful operations. Specifically, his input and efforts were fundamental in effecting key improvements at three of our manufacturing sites in Mexcio, Europe, and Asia Pacific. A s a management consultant, he showed relentless commitment to improving Navico's manufacturing and supply chain operations, reflecting his personal focus on "navigating to results". Joerg built on Navico's strengths to optimize the manufacturing-model overall, implementing step-changes and giving recommendations to leverage existing capabilities and culture. His optimism and "can-do" attitude combined with a creative out-of-the-box approach for initiating change has been a great catalyst in driving Lean-implementation of three plants in Ensenada/Mexico, New Zealand, and Norway, ensuring over USD 5 million to bottom-line in savings and throughput-increase. The participant feedback in these change programs has been exceptionally positive. In Joerg's role as Interim manager for our manufacturing plant in Mexico, which employs 1500, and has a USD 1 million per day throughput, he led the team in a crisis-like situation to meet stretch-targets, increasing output from USD 14 million to USD 22 million within two months. The results speak for themselves: The combined impact of Joerg's efforts to EBITDA was approximately USD 8 million. I can confidently recommend Joerg Muenzing for any position or assignment in the area of manufacturing or supply chain management. I firmly believe his skills and experience will measure up to any challenge."

CEO, Marine Electronics

"I was very satisfied with what we accomplished in 6 weeks. I would say that your version of this is more extreme then we have learned before and I think I know why. You have to be extreme to get real change and I believe 100% in your way. We met all of my expectations and more. Production output improved from 400 to 1500 units per week. Thanks a lot for what you have done with my people and organization; it would never have been possible without your skill and experience. You pushed us over a hill that we couldn’t have done ourselves."

General Manager, Norway

[…] Impact: see Navico […]