Agile Lean-Six-Sigma training for managers, specialists, operators to improve processes and get certified as White Belt, Yellow Belt, Green Belt, Black Belt.

The Agile Lean Six Sigma course is for program leaders, master trainers, and organizational change agents to accelerate projects with Agile for quicker delivery, tackle waste with Lean for high efficiency, and reduce variability with Six Sigma for higher quality and customer satisfaction.

Cases, when to use:

- Excessive waste, variability, overload

- Unreliable processes deliver unpredictable results

- Continuous firefighting, stress to “make the numbers”

Clients, for whom:

- Managers and team leaders

- Process owners, controllers, engineers

- Anyone who wants to get stable, predictable results

Process, how it works:

- Online training course with personal coaching support

- Apply agile for speed, lean for efficiency, six sigma for stability

- Learn proven process improvement strategies; templates included

Benefits, what to gain:

- Status and recognition as cost reduction expert

- Practical strategies for sustainable cost savings

- Delivering financial impact boosts career and pay

What It Is and For Whom

The Agile Lean Six Sigma (ALSS) training build practical skills in process analysis, solution design, and change management to deliver measurable impact. As an ALSS student, you will learn how to uncover hidden potentials and systematically drive performance improvements, creating real benefits for you and your company. Over the past 10 years, we have trained over 5k champions on 4 continents who delivered over $85 million hard savings from their first training project alone, that $17k average per trainee. Start applying proven tools and techniques to ‘move the needle’ of key performance indicators (KPIs) in scope.

- Kick-start your professional improvement journey

- Receive live coaching from a senior consultant

- 100% online, self-paced, with certification exams

- Get certified as a White, Yellow, Green, Black Belt

- Eliminate wastes and boost efficiency with Lean

- Accelerate project implementation with Agile

- Reduce variability to boost quality with Six Sigma

- Translate opportunities into formal project charters

- Take quizzes to check your knowledge, get feedback

- Apply learning to create measurable improvements

- Standardize processes and create work instructions

- Deliver real benefits by reducing effort, time, cost

- Download toolkits and ready-to-use templates

Why You Want It

- Build skills to boost your career by simultaneously improving quality, speed, productivity, and cost. Your will learn how to apply problem-solving and performance-improvement techniques to create breakthrough results for your process, team, and company.

- The training helps you to reduce waste and complexity with Lean to improve flow and efficiency, eliminate the causes for variations and defects with Six Sigma to boost quality and customer satisfaction, and accelerate improvements with Agile through incremental, iterative project delivery.

- Agile Lean Six Sigma courses are for mangers and functional specialists to reduce variations and defects by up to 90%, measurably increasing productivity, cost, quality, and customer satisfaction with a return on investment of 10x. Nothing to lose, much to gain. Boost skills and results now!

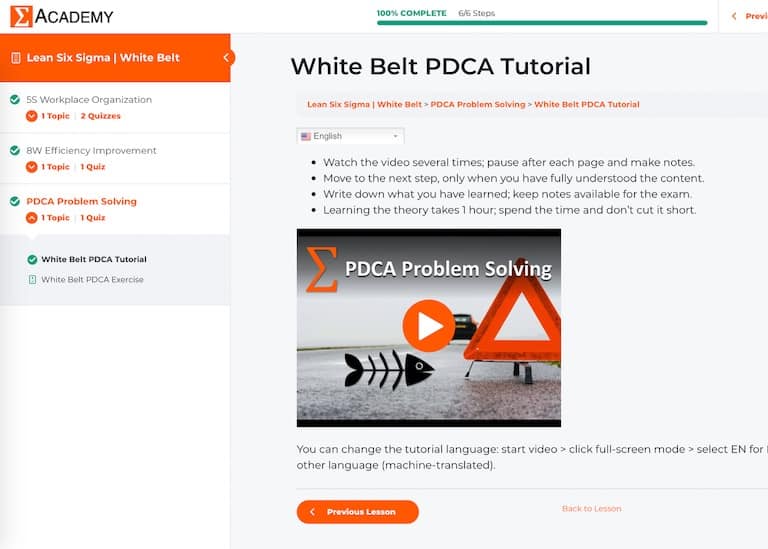

Agile Lean Six Sigma | White Belt

Online course for beginners to systematically organize workplaces, identify efficiency improvements, and formally solve basic problems.

Agile Lean Six Sigma | Yellow Belt

Coaching-guided intermediate course to identify issues, develop project charters, apply spot-improvements, measure impact, and create work instructions.

Agile Lean Six Sigma | Green Belt

Coaching-supported advanced course to develop business cases, analyze value streams, execute cross-functional projects, design operating standards.

White Belt Topics

- 8 Wastes Identification

- 5S Method and Audit

- Fishbone 6M Categories

- 5 Why, simple Problems

- PDCA Process, Template

Quotes from course participants:

- “I can see things clearly now”

- “This is totally common sense”

- “The impact of your coaching on my life has been massive”

- “Everyone should learn this”

- “I’m getting back in control”

- “A new way of working”

- “This was practical and fun”

- “Why haven’t we thought about this before?”

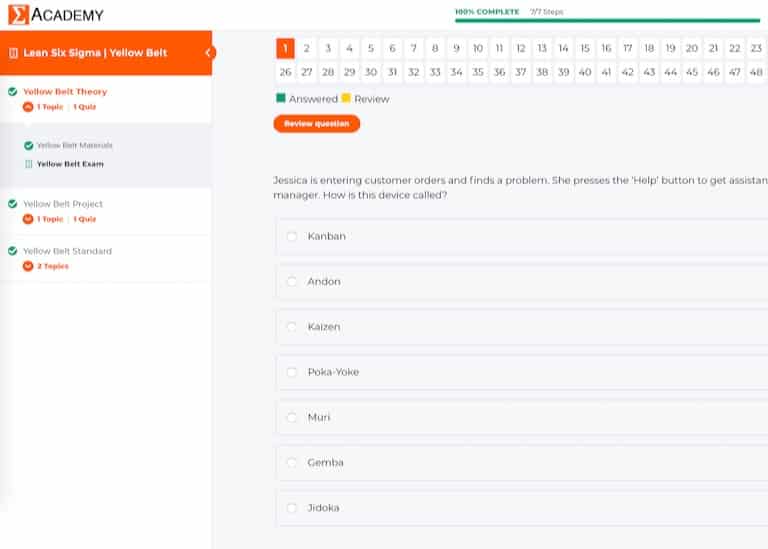

Yellow Belt Topics

- Agile Project Charter

- 5S as a System

- 8W “DOWNTIME”

- Basic Control Charts

- Abnormality Signals

- Batch and Queue

- Cellular Concept

- Continuous Flow

- Cycle Time Basics

- Downtime and Efficiency

- Error-Proofing, Poka-Yoke

- First-In First-Out FIFO

- Fishbone Ishikawa 6M

- Kaizen Principles, Project

- OPL One Point Lesson

- Overproduction

- Problem Solving PDCA

Green Belt Topics

- Agile Sprint Planning

- Daily Scrum, Sprint Review

- Cycle, Takt, Tact, Pitch

- Inventory Optimization

- Just-in-Time JIT

- Lean Manufacturing

- Lean Admin & Service

- Load-Leveling, Heijunka

- Management Boards

- Product and Service Matrix

- Pull Systems: A and B

- Setup Reduction SMED, RTS

- Skill-Matrix

- Spaghetti Chart

- Standard Operating Procedure

- Total Productive Maintenance

- Value Stream Mapping VSM

Black Belt Topics

- Product Roadmap Creation

- The 7 Quality Control Tools

- Cost of Poor Quality COPQ

- Profit Per Hour PPH

- Zero-Based Budgeting ZBB

- Flexibilizing, Balancing

- Flow Production, Service

- Non-Performance Cost NPC

- Process Capability Cp, Cpk

- Measurement System GR&R

- Pull Systems: A, B, C

- Risk Analysis FMEA

- Strategic Planning, Roadmap

- Strategy Deployment, X-Matrix

- Cycle Time, Takt, Pitch

- Yield FPY, FTY, RTY

- Variability Reduction Methods

How Courses Work: Lean Theory → Apply Theory → Implement Improvement → Earn Certificate

Lean Six Sigma - Program Brief

How it works:

The program consists of three parts: training, application, certification. During the training, participants learn about principles, tools, and techniques. Right after the training, they apply learnings in practical improvement projects to build real skills and create measurable benefits.

How long it takes:

The time to become a White Belt takes 2 days effort over a 1-month period, a Yellow Belt takes 5 days effort over 2 months, a Green Belt requires 10 days effort during 2 months, and a Black Belt is certified after implementing a transformation program, requiring at least 30 days effort over a 6-month period.

Who is involved:

The four key roles are sponsor, student, trainer, and controller. The sponsor initiates the program, provides context and allocates resources. The student invests time to read the material, complete the exercises, develop a project, and implement improvements. The trainer reviews progress and provides coaching feedback. For Yellow Belt and above, the project controller validates financial benefits created.

What you can expect:

Certified Lean Six Sigma champions are able to see and act on opportunities that were not known or not addressed before. By improving quality, efficiency, and flexibility, those champions generate real benefits from reduced defect rates, faster delivery, lower cost, and higher customer satisfaction.

How much it costs:

Courses generate a positive return as skills are applied and improvements implemented. Most projects achieve full payback within the implementation period, delivering a financial benefit 10x over tuition fees (ROI), making it a worthwhile investment!

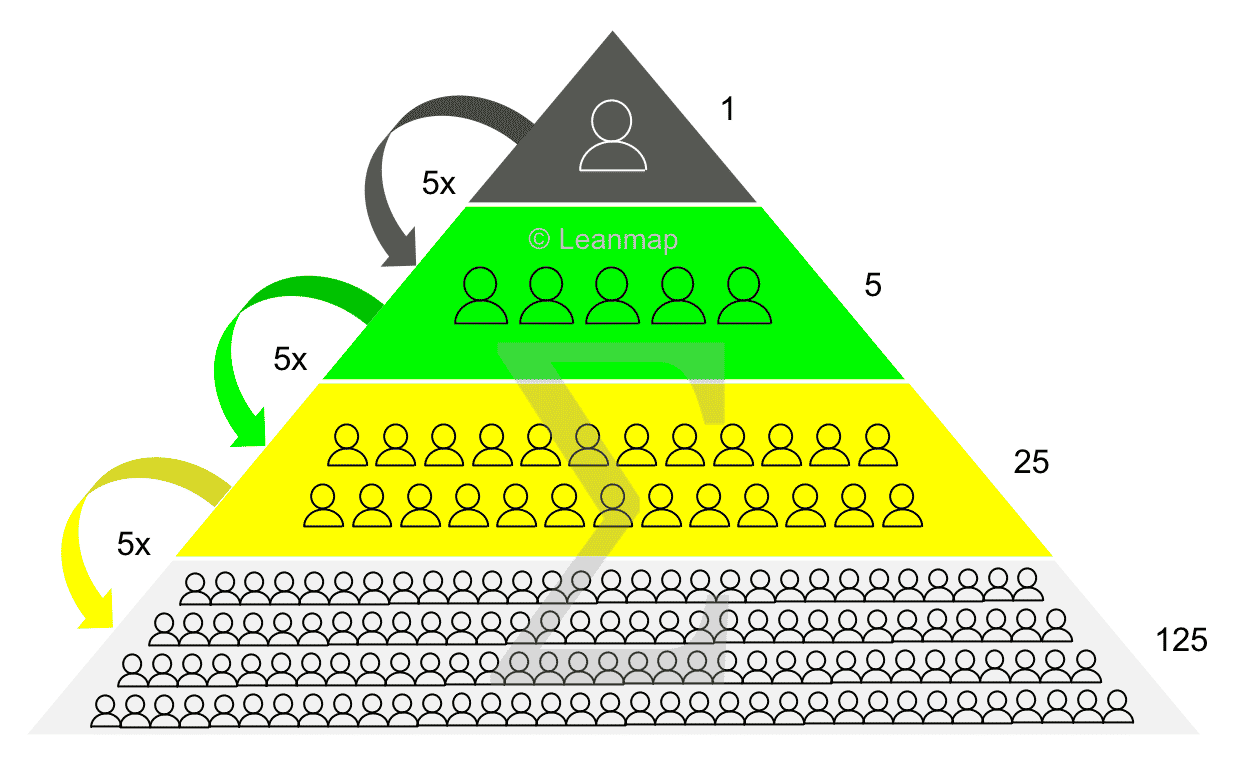

Building the Agile Lean Six Sigma Skill Pyramid

The training program establishes a Skill Pyramid to cascade knowledge from expert down to the frontline, involving people at all levels of the organization, including senior management; like one CEO puts it: “we are taking our own medicine”. Employing a train-the-trainer model means that certified Yellow Belts, Green Belts, Black Belts develop and certify people below them. Each Black Belt supports at least 5 Green Belts, of which each Green Belt supports at least 5×5 = 25 Yellow Belts, of which each Yellow Belt supports at least 5x5x5 = 125 White Belts. At 5x-leverage, one Black Belt supports an organization of 200 people, of which 160 or 80% participate and attain Lean Six Sigma certification.

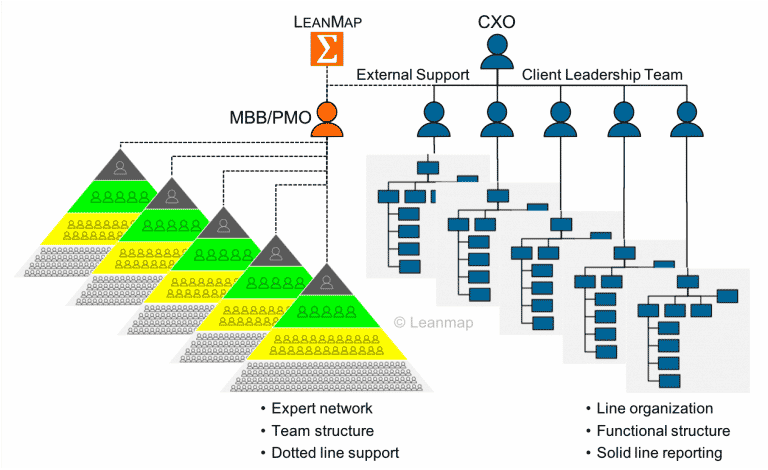

Organizational Structure for Continuous Improvement

The Skill Pyramid is a professional support structure that allows people to connect with each other, exchange experiences, develop new ways of working, and provide expert knowledge and coaching support. For example, a customer service agent who is working on a Yellow Belt project receives support from an accountant, who is a certified Green Belt and worked on a similar project before. Leanmap helps clients to design and implement such professional support structures that leverage expert-skills across functions, divisions, and sites. As Master Black Belt (MBB) or Project Management Officer (PMO) we provide interim management assistance to ensure that the program delivers the desired change and impact (→ how to engage a consultant).

Learn Business Transformation Skills: Self-Guided and Coach-Supported Certification Courses

5k+ Graduates from 20+ Countries on 4 Continents

Automotive Problem Solving Program: Training Trainers

Building problem-solving skills to systematically identify cause-effect relationships and effectively eliminate underlying root causes. By doing so, costly product and process failures are being prevented.

Training Wrist’s Staff in Pursuit of Lean Ship Service

With focus on warehouse and back-office operations, 614 champions completed their Lean projects, improving response time to customers and on-time-in-full (OTIF) delivery performance to vessels.

Lean Six Sigma Black Belt Certification in Mexico

After a one-year project implementation phase champions from Australia, Argentina, Brazil, Mexico, Netherlands and Switzerland completed the Lean training and received their Black Belt certificates.

Lean Leadership Training at Wrist: “We’re taking our own medicine”

Performance Improvement Program (PIP) was kicked-off by Wrist Ship Supply with an initial training of the leadership team in Aalborg, Denmark to build critical skills.

Lean Six Sigma Black Belt Certification in Brazil

Lean champions who attained Black Belt level are now proficient in value stream mapping in manufacturing and service, root-cause identification and elimination, process-redesign and standardization.

Lean Six Sigma Yellow Belt Certification Singapore

Trainees at all levels of the organization learned how to effectively reduce waste, variability, and inflexibility (3 losses), while getting certified as Lean Yellow Belts.

PDCA Problem Solving Certification for Givaudan Singapore

Removing causes to prevent repeat problems is a foundational skill for key people, such as managers, supervisors and specialists to systematically improve right-first-time (RFT) rate.

Executive Sponsor Training in Change Management

Executive Sponsor Training (EST) for senior managers to build solid skills in Lean management, becoming more effective sponsoring and steering change-programs across functions and sites.

Build Skills to Boost Process Performance

White Belt

«Beginner»-

Course: 100% online and self-guided, without coaching support.

-

Purpose: build certified capability at the «Beginner» level; introductory course for everyone, from janitor to executive.

-

Schedule: 2 days effort within a 1-month period to learn the theory, organize a workplace, solve a problem, and attain certification.

-

Exit competencies: organize workplace with 5S, identify and reduce the 8 deadly wastes to improve quality and efficiency, solve simple problems with PDCA.

-

Benefit: spot-improvement to create a visible or even measurable benefit, worth $500 (self-certified).

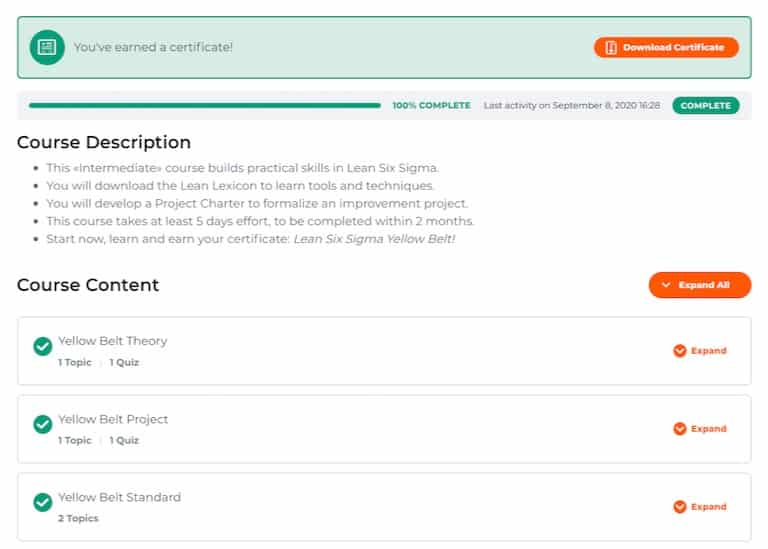

Yellow Belt

«Intermediate»-

Course: 100% online with expert validation of project and impact.

-

Purpose: build certified capability at the «Intermediate» level for anyone working with a computer, machine, or process.

-

Schedule: 5 days effort within a 2-month period to learn the theory, implement a small improvement project, and attain certification.

-

Exit competencies: improve process quality and efficiency by reducing wastes, develop project charters, solve basic problems, train and certify White Belts.

-

Benefit: functional improvement to deliver at least 10% performance gain or $10,000 financial benefit.

Green Belt

«Advanced»-

Course: 100% online with expert validation and monthly coaching.

-

Purpose: build certified capability at the «Advanced» level for managers and specialists, responsible for teams or assets.

-

Schedule: 10 days effort within a 3-month period to learn the theory, implement a cross-functional improvement, and attain certification.

-

Exit competencies: map value streams, implement flow and pull, apply statistical analysis and controls, solve advanced problems, train and certify White and Yellow Belts.

-

Benefit: cross-functional project to deliver at least 20% performance gain and $30,000 financial benefit.

Black Belt

«Expert»-

Course: 100% online, coaching, validation, peer group, live support.

-

Purpose: build certified capability at the «Expert» level for program leaders and organizational change agents.

-

Schedule: 30 days effort within a 6-month period to learn the theory, implement a transformation project, and attain certification.

-

Exit competencies: lead cross-site transformation programs, apply statistical methods to analyze and solve complex problems, train and certify White, Yellow, Green Belts.

-

Benefit: transformation project to deliver at least 30% performance gain and $90,000 financial benefit.